Our journey to Mexico City began with a flight from Prague via Paris. After checking in at the airport, we decided to strengthen our...

As a company that produces high-quality adhesive solutions, we understand the importance of meeting our customers’ unique requirements. One of the most common industries we work with is the paper tube manufacturing industry, where the primary concerns are strength, price, and quality.

Our Process for Testing Adhesives

Our process typically begins with an inquiry from the customer, or we may approach potential customers with an offer tailored to their needs. We prioritize providing our customers with adhesives that have consistent parameters.

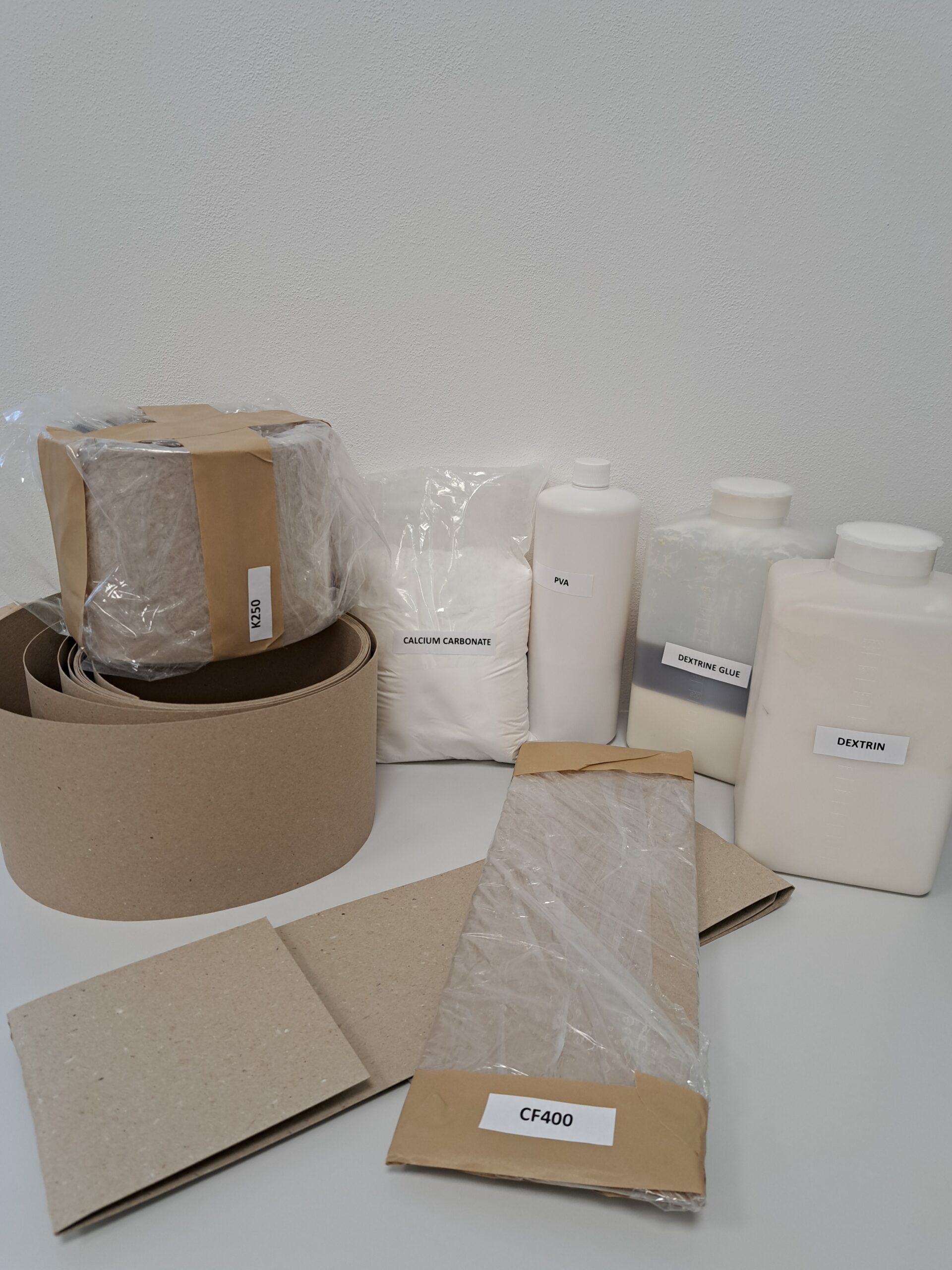

To begin the testing process, we ask for samples of the paper used and the parameters of the currently used adhesive. We analyze the adhesive’s viscosity, pH, stickiness, density, and dryness to create an optimized solution for everyone.

Once we’ve analyzed the samples, we provide a quotation and send samples of our solution. The packaging size of these samples depends on the needs of the customer. We usually offer PET bottles for laboratory testing, while we offer barrels of approximately 50 kg or IBCs of approximately 1000 kg for testing in production.

We then go directly to the customer’s facility and participate in the production tests to fine-tune everything to the customer’s satisfaction. (osobní účast) During this process, we may identify any imperfections or suggest procedures to further improve the product.

Efficient Solutions for Common Adhesive Problems in the Paper Tube Industry

Our team of experts can provide tailored adhesive solutions that can address specific challenges faced by customers in the paper tube industry, such as high humidity or extreme temperatures. Additionally, we offer technical support and assistance to ensure our customers are maximizing the performance and efficiency of our adhesive solutions. At our company, we offer adhesive solutions to address the most common issues, such as:

- Quality of supplied adhesive: Ensuring the adhesive is consistent in quality every time it is delivered, which contributes to predictable results and reduced waste during production.

- Quality of manufactured tubes: Factors such as the flat a radial crush, moisture content, drying time, and ovality are essential aspects that need to be considered to ensure a high-quality final product.

- Production parameters: Maintaining or improving production speed is essential for operational efficiency while also considering issues like slipping on the mandrel that can impact the overall process.

- Price: Providing cost-effective adhesive solutions is crucial for customers to optimize their expenses while maintaining product quality and performance.

With our adhesive solutions, customers can improve their production processes, create high-quality paper tubes and protect edges efficiently.

Providing Adhesives in a Variety of Quantities and Sizes

We understand the importance of customer satisfaction, and that’s why we offer a guarantee that allows customers to return adhesive products that do not meet specifications without paying. This guarantee ensures confidence in our products and allows our customers to trust that we provide quality adhesives that meet their needs.

Customers can place an order if they are satisfied with our solution. We offer adhesives in small quantities, such as barrels of approximately 50 kg or IBCs of approximately 1000 kg. For bulk mixture, we provide paper bags in sizes adjusted to the customer’s needs, most commonly 20 or 25 kg paper bags, but we can also accommodate paper bags sizes of 22 kg. Alternatively, we can provide big bags of approximately 1000 kg.

We take pride in our ability to work closely with our customers and provide them with the highest quality solutions tailored to their unique requirements. Our thorough testing process and commitment to customer satisfaction ensure that we can continue to meet the evolving needs of the paper tube manufacturing industry.